Putlogs for scaffolds are used to support and stabilize scaffolding platforms, playing a crucial role in construction safety and efficiency. These horizontal members extend perpendicularly from the scaffold frame, providing a base for the working platform and ensuring its stability.

Putlogs come in various types, materials, and specifications, catering to different construction requirements. Their proper placement and spacing are essential for maintaining the integrity of the scaffold structure.

1. Introduction to Putlogs

Putlogs, also known as scaffold putlogs or scaffolding ledgers, are essential components of scaffolding systems used in construction. They are horizontal members that extend from the standards (vertical posts) of a scaffold to support the working platform. Putlogs play a crucial role in ensuring the stability, strength, and safety of scaffolding structures.

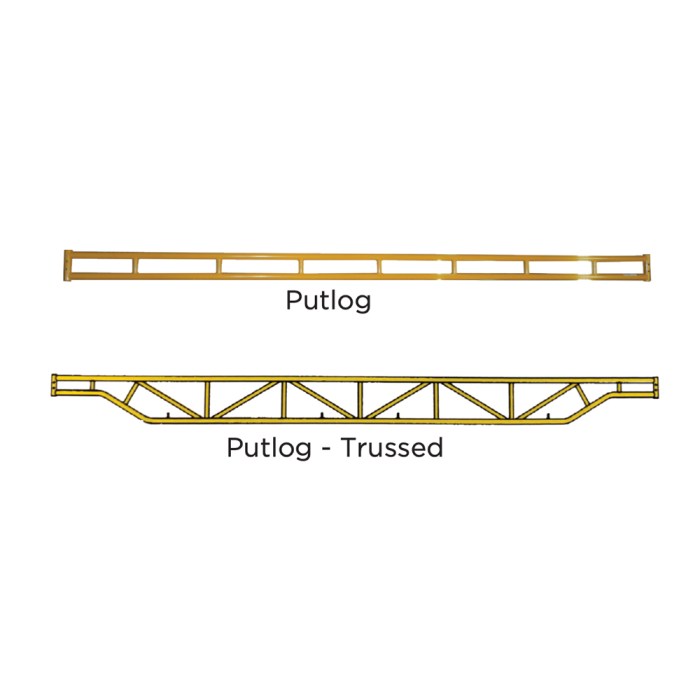

Putlogs come in various types, including:

- Solid putlogs:Made from solid timber or metal, these are the most common type of putlogs.

- Tubular putlogs:Constructed from hollow steel tubes, they are lightweight and easy to handle.

- Adjustable putlogs:Feature a threaded or telescopic mechanism that allows for adjustment in length.

The materials used for putlogs include wood, steel, and aluminum. Wood putlogs are traditional and cost-effective, but they are susceptible to moisture damage and warping. Steel putlogs are stronger and more durable, but they are also heavier and more expensive.

Aluminum putlogs offer a balance of strength and weight, making them a popular choice for many applications.

2. Applications of Putlogs: Putlogs For Scaffolds Are Used To

Putlogs are primarily used to support and stabilize scaffolding platforms. They are inserted into the couplers (clamps) attached to the standards and extend horizontally to create a stable base for the working platform. The platform is then laid perpendicularly across the putlogs, creating a safe and level surface for workers to operate on.

The proper placement and spacing of putlogs are crucial for the safety and stability of the scaffolding. Putlogs should be spaced evenly and securely fastened to the standards to ensure that the platform is level and can withstand the weight of workers and materials.

3. Safety Considerations for Putlogs

Using putlogs in scaffolding systems requires careful attention to safety. Potential hazards associated with putlogs include:

- Falling putlogs:Putlogs that are not properly secured can fall and injure workers or damage equipment.

- Scaffold collapse:Improperly installed or overloaded putlogs can lead to scaffold collapse, posing a significant risk to workers.

- Tripping hazards:Protruding or misplaced putlogs can create tripping hazards for workers.

To ensure the safe use of putlogs, it is essential to follow regulations and standards governing their installation and maintenance. These regulations may vary depending on the jurisdiction, but generally include requirements for:

- Proper selection and sizing of putlogs based on the intended load.

- Secure attachment of putlogs to the standards using appropriate couplers.

- Regular inspection and maintenance of putlogs to ensure they are in good condition.

4. Alternatives to Putlogs

While putlogs are widely used in scaffolding systems, there are alternative methods for supporting scaffolding platforms. These alternatives include:

- Trestles:Self-supporting scaffolding structures that do not require putlogs.

- Scaffolds with built-in platforms:These scaffolds have integrated platforms that eliminate the need for putlogs.

- Hanging scaffolds:Suspended from above, these scaffolds do not require putlogs for support.

The choice of alternative depends on factors such as the height and configuration of the scaffold, the weight of the platform and materials, and the specific application.

5. Future Developments in Putlog Systems

Advancements in materials and engineering are continuously improving the performance and safety of putlog systems. Emerging technologies and innovations include:

- Composite putlogs:Made from a combination of materials such as fiberglass and polymers, these putlogs offer increased strength and durability.

- Smart putlogs:Equipped with sensors that monitor strain and load, these putlogs provide real-time data on the condition of the scaffold.

- Self-leveling putlogs:Utilizing hydraulic or mechanical mechanisms, these putlogs automatically adjust their length to maintain a level platform.

These developments are expected to enhance the safety and efficiency of scaffolding systems, leading to improved working conditions for construction workers.

Query Resolution

What are the primary functions of putlogs in scaffolding?

Putlogs primarily serve to support and stabilize scaffolding platforms, ensuring the safety and stability of the structure.

What factors determine the selection of putlogs for a particular scaffolding system?

The choice of putlogs depends on factors such as the height and load-bearing requirements of the scaffold, as well as the materials and specifications of the putlogs themselves.

What are the key safety considerations when using putlogs?

Proper installation, regular inspection, and maintenance are crucial for ensuring the safety of putlogs. Regulations and standards govern their use, and adherence to these guidelines is essential.